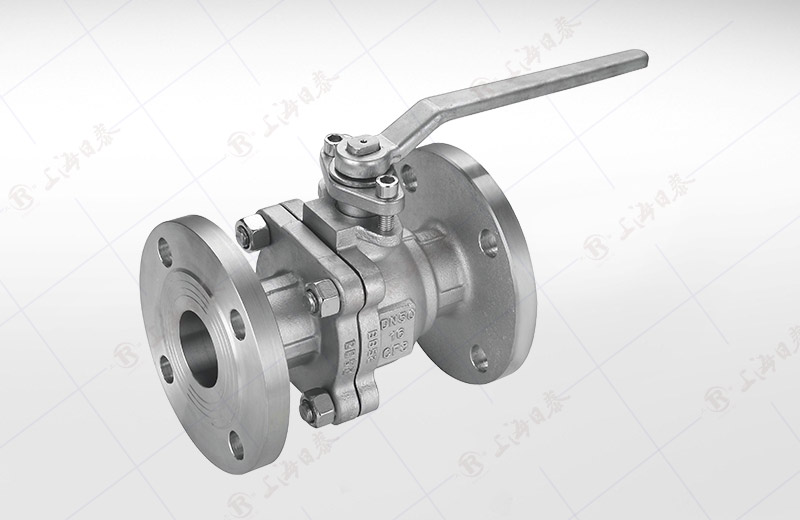

1. Floating ball valve lip seal seat, ensure that the valve sealing performance is good, small friction coefficient, small operating torque.

2. Anti-flying structure of the valve stem: the stem is of lower mounting type to prevent flying out under pressure. At the same time, it can form metal contact with the valve body after fire to ensure the stem seal.

3. Fire and anti-static device (soft sealing floating ball valve).

4. With locking device.To prevent incorrect operation of valve switch, there are locking holes in the fully open and fully closed position of the valve to ensure that the valve is in the correct position.

5. Floating ball valve is suitable for frequent operation, fast opening and closing;Relatively small size, light weight, easy to maintain;Not subject to the direction of installation;Low fluid resistance, no vibration, low noise.

Product model: Q41F/H/Y

Main material: carbon steel, stainless steel, alloy steel

Nominal diameter: DN15 ~ 200mm

Pressure range: PN1.0 ~ 10.0MPa

Operating temperature: -29℃ ~ +200℃

Application: It is applicable to switch the flow direction of medium in pipeline systems of water supply, petrochemical, metallurgy, mining, light textile, energy, papermaking, food, steel and iron, as well as to diverge or mix the medium fluid.