Ball Type Universal Expansion Joint

Product details

In the process of daily use of the pipeline, due to the difference in temperature between the ambient temperature and the installation of the pipeline, the pipeline will produce a certain amount of elongation;Due to the settlement and deformation of the foundation, the pipeline will deviate from the initial position.At the corner, there will be a large deformation, displacement, deflection Angle, stress concentration and other phenomena.In severe cases, it will lead to seal failure and leakage or pipe strength failure and fracture failure.In order to avoid this kind of phenomenon, it is necessary to find a structure design that can absorb large deformation, displacement, deflection Angle and stress concentration, so as to ensure the safety of pipeline.

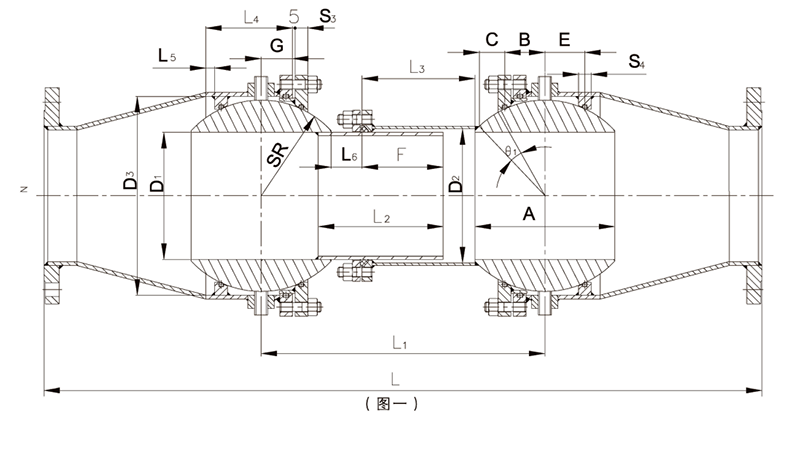

Structural state during installation (see FIG. 1 Structural diagram during installation)

FIG. 1 Schematic diagram of installation

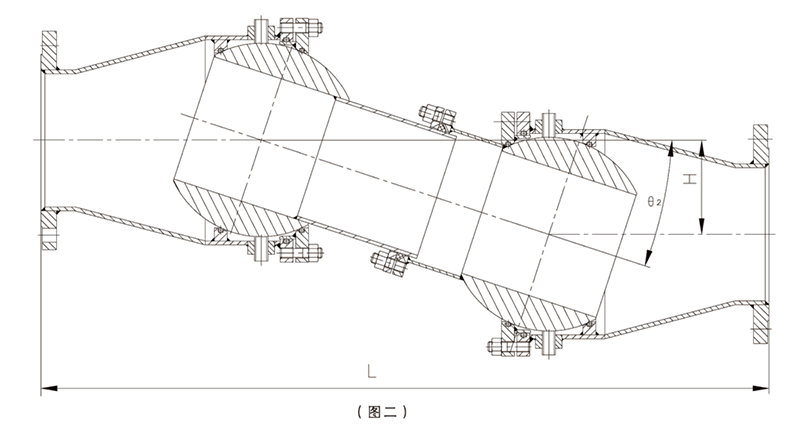

Structure state at work (see Fig.2 structure diagram at work)

FIG. 2 Schematic diagram of working time

Working principle

When installing the pipe, install the spherical universal telescopic device in the place where settlement is easy to happen or stress of the pipe is easy to be concentrated.At this point, the active inner sleeve is extended into the fixed jacket tube, and the spherical universal telescopic device is in the shortest state.When the pipeline is put into use, it may produce settlement and displacement due to temperature difference, soil covering change and other factors.It causes large deformation, displacement, deflection Angle and stress concentration of the pipe.After the spherical universal telescopic device is adopted, the movable inner sleeve slides out of the fixed jacket tube to compensate the elongation.The universal joints at both ends can freely move within the designed Angle range to play the role of absorbing Angle deformation.